Heat Treatment of Aluminum Castings

The heat treatment process is used to improve the mechanical properties of the aluminum casting, by changing the shape or location of some of the elements within the aluminum alloy matrix.

The strength (and ductility) of the castings can be increased by breaking-up the larger silicon particles into smaller, more evenly distributed particulate.

The heat treatment process also relocates some of the soluble compounds within the alloy, moving them into the softer areas of the matrix to improve the overall alloy rigidity.

How Le Sueur Incorporated Uses Heat Treating

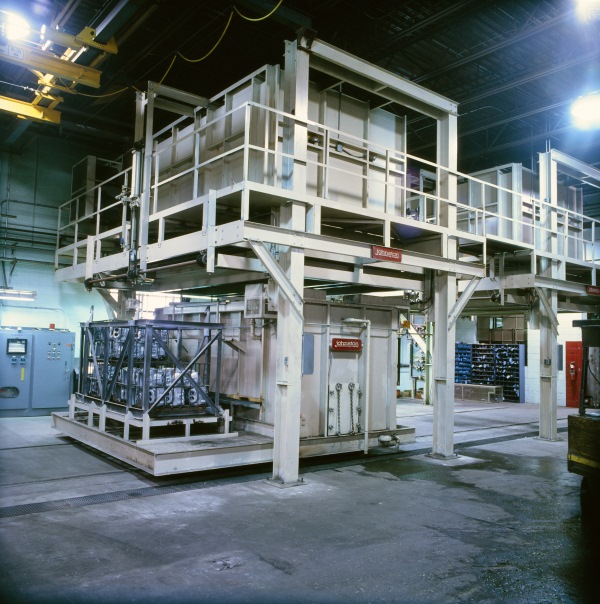

LSI uses five in-house solution heat-treat ovens to bring the castings near their original melting points. The castings are then immediately quenched in hot water, temporarily suspending some of the soluble compounds. The castings are then moved into an age oven and re-heated to aging temperatures. The soluble compounds precipitate back out in a more favorable location within the microstructure, improving the overall casting strength.

In-house Heat Treatment methods include T5, T51, T6, T61, T7 and T71.

Learn More About Heat Treating for Aluminum Casting Projects

Le Sueur Incorporated specializes in producing dimensionally complex, pressure tight aluminum castings and thermoplastic injection molded components. We offer complete in-house precision machining, finishing and assembly. Please contact us to learn more about our capabilities and how we can best assist with your casting needs!