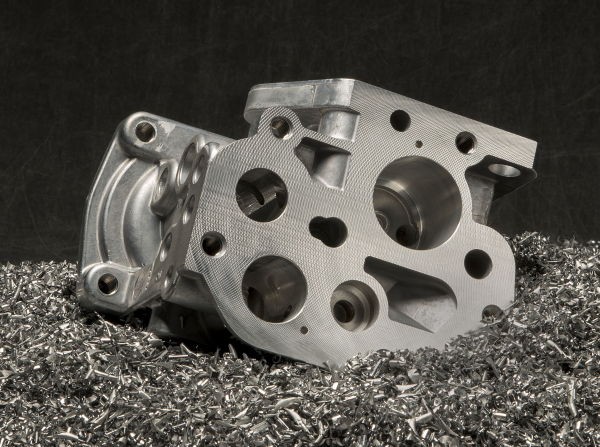

Precision Casting Machining

Le Sueur Incorporated is a vertically integrated supplier offering multiple manufacturing processes. Casting, machining and sub-assembly processes are performed in-house. LSI works with local suppliers to provide finishing operations including coating (i.e. painting, plating, anodizing and chromate), specialized cleaning, impregnation and other value added services so that our customers receive a complete ready to use product.

Le Sueur Incorporated provides complete horizontal and vertical machining, CNC turning with live tooling capability, horizontal and vertical multi-spindle, complete pressure testing (air decay/air under water) and complete assembly as required.

Machining Equipment List

4 – Mazak Model Nexus 5000 Horizontal Machining Center, 120 tools, 18,000 rpm, 360,000 position indexer, high pressure through tool coolant

1 – Mazak Model Nexus 5000 Horizontal Machining Center, 120 tools, 18,000 rpm, full 4th axis, high pressure through tool coolant

1 – Mazak Model Nexus 5000 Horizontal Machining Center, 60 tools, 18,000 rpm, 360º position indexer, high pressure through tool coolant

1 – Mazak Nexus Lathe Model 300M, 10 inch chuck, tail stock, live tooling

1 – Makino Model A61, 40 tools, 1000 PSI , full 4th axis, through tool coolant

1 – Makino Model A51 Horizontal Machining Center, 60 tools, 14,000 rpm, full 4th axis, high pressure through tool coolant

1 – Mazak Nexus Lathe Model 100, 8 inch chuck

1 – Mazak 530C Smart Full 4th Axis, 14000 rpm

1 – Fanuc T-14iBL Robodrill Vertical Machining Center, 10,000 rpm, rigid tapping, Tsudakoma RC-150 full 4th axis, 27.000x13.000x13.000 travel

1 – Fanuc D-14MiA5 Robodrill Vertical Machining Center, 10,000 rpm, rigid tapping, Tsudakoma RC-150 full 4th axis, 16.700x15.750x11.800 travel

Air Decay Leak Testing Equipment

4 – Cincinnati Sentinel C20, One Program single station unit

1 – Cincinnati Sentinel I21, Seven Program multiple station unit

All units have self-testing devices, auto calibration and 10-200psi capabilities.

1 – Quality First Systems J00112 Pneumatic Pressure Tester

2 – Submersion Leak Tester

Le Sueur Incorporated specializes in producing dimensionally complex, pressure tight aluminum castings and thermoplastic injection molded components. We offer complete in-house precision machining, finishing and assembly. Please contact us to learn more about our capabilities and how we can best assist with your casting needs!