Engineered Aluminum Casting Products and Solutions

Le Sueur Incorporated is unique because we offer multiple aluminum casting processes including Permanent Mold, Sand Casting and Die Casting. Offering all three processes allows us to provide unbiased recommendations when assisting our customers. We use our expertise in the nuances of each method to select the best casting process, alloys and finishing processes to achieve a product’s specific requirements.

Aluminum Casting Experts Offer Tailor-Made Solutions

Early engagement with LSI's process of dedicated engineering staff is essential to achieve a mutually successful project. These engineering professionals assist our customers in the product development process by incorporating the most advantageous tooling and aluminum casting practices. Our engineers are experts in multiple casting processes. Tooling is built off each unique scenario. Together with our customers, a product design is evolved for the selected casting and manufacturing processes to produce the most cost-efficient and robust part.

Considerations for Selecting the Best Aluminum Casting Process

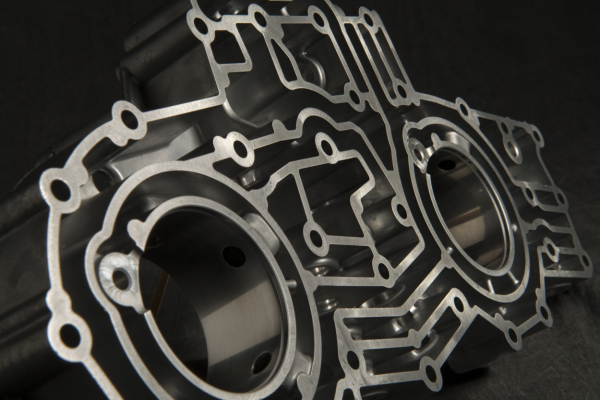

Aluminum casting is a widely used process that involves pouring or injecting molten aluminum into a mold to repetitively create complex and detailed parts. There are many types of casting processes. Each manufacturing process uses different types of molds to produce the casting and involves either pressure or gravity to fill the mold with molten aluminum alloy.

There are several considerations in selecting the right aluminum casting process for your application. Review the considerations below to learn more or contact our experts to discuss any questions you have regarding which aluminum casting process is best for your application.

|

Casting Consideration |

Sand Casting |

Die Casting |

Permanent Mold |

|---|---|---|---|

|

Surface |

Low |

High |

Medium |

|

Casting |

Low |

High |

Medium |

|

Tool Cost |

Low |

High |

Medium |

|

Production |

High |

Low |

Medium |

|

Production |

Low |

High |

Medium |

|

Mechanical |

Medium |

Medium |

High |

|

Structural |

High |

Medium |

High |

|

Pressure |

Medium |

High* |

High |

|

Internal |

Medium |

Low |

High |

|

Near Net |

Low |

High |

Medium |

|

Ease of |

High |

Low |

Medium |

|

Complexity |

Low |

High |

Medium |

|

Tool Life** |

Low |

High |

Medium |

|

Tool |

Low |

High |

High |

|

Production |

Low |

Medium |

High |

* Pressure tightness in die castings is improved by incorporating Squeeze Pin Technology.

** Tool Life is highly dependent upon the type of tooling, casting geometry and surface finish requirements.

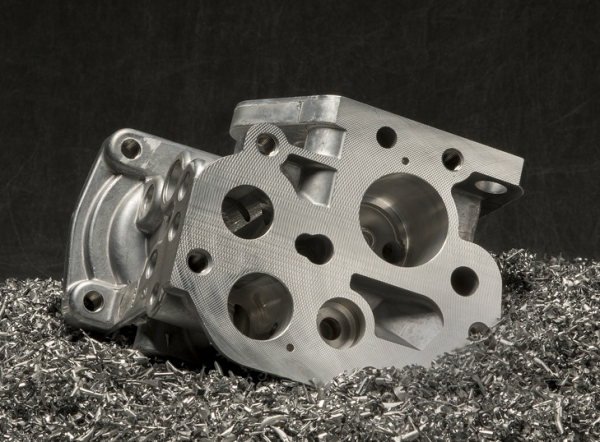

Permanent Mold Casting Capabilities

As an industry-leading supplier of aluminum castings and plastic injection molding, Le Sueur Incorporated offers both semi-permanent and permanent aluminum mold casting services. Our engineers are experienced in finding the most cost-effective, efficient solution for your low pressure permanent mold and tilt pour permanent mold casting needs. Our capabilities include in-house precision machining, finishing, and assembly.

Discuss Your Aluminum Casting Project with LeSueur

Le Sueur Incorporated specializes in dimensionally complex, pressure-tight aluminum castings and thermoplastic injection molded components. We offer complete in-house precision machining, finishing, and assembly. Please contact us to begin your project!